Process & Equipment

SMT – Layout

Our SMT lines use nitrogen reflow all the times and are equipped with Auto Solder Printer, SPI, Component Verify System and 100% AOI to ensure soldering quality and stability.

SMT Line A

YAMAHA YCP10 Auto Solder Printer

ZHX V860 SPI

YAMAHA YSM20R High-speed mounter

YAMAHA YSM10 Mounter

SAMSUNG SM482 Mouinter

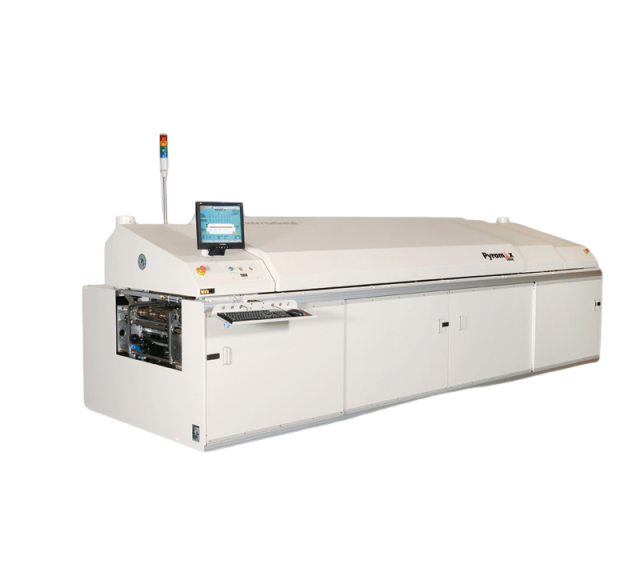

BTU Pyramax 125N Reflow

SMT Line B

GDK X5 Auto Solder Printer

ZHX V860 SPI

YAMAHA YSM20R High-speed Mounter

SAMSUNG SM482 Mounter

YX LFHACRF Reflow

SMT Line C

The facility is currently under construction and is expected to begin production in 2026Q1.

Air Shower

Component Verify System

Solder Paster Storage Area

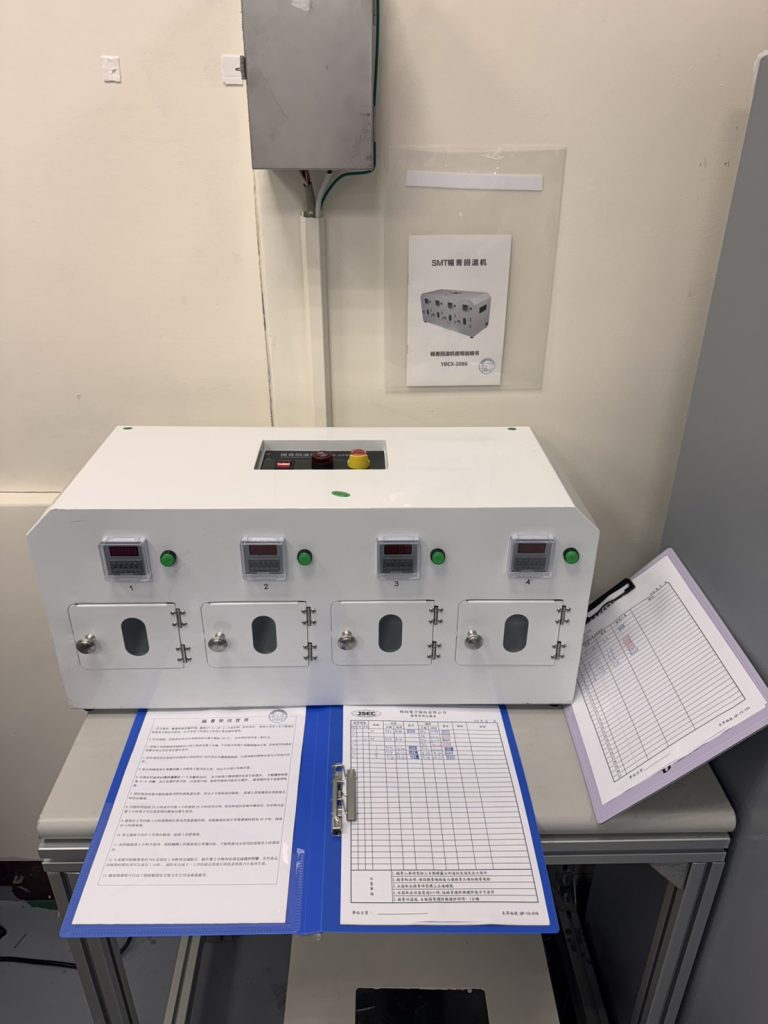

Solder Paste Warmer

SMT – Capability

We have expertise in BGA inspection, reballing, and rework, with proven experience handling BGA packages exceeding 1,000 balls. Our SMT capabilities also support placement of components with over 1,500 chips.

| ITEM | JSE CAPABILITY |

|---|---|

| SMT (Pick & Place) | Mounting Accuracy : +/-0.05mm |

| Chip Component | Min : 0201, >1500 chips |

| IC (BGA/QFN) | Min : Pitch 0.30mm, ɸ0.20mm, >1000 balls |

| PCB | Max length : 510mm, Max width : 460mm, experience : 8L / T=3.0mm / FPC / R-FPCB |

DIP – Layout

We have two DIP lines with flexible manpower to meet different process needs. Testing and assembly are arranged based on requirements.

DIP Line

Rework & Visual Inspection Line

Assembly Line

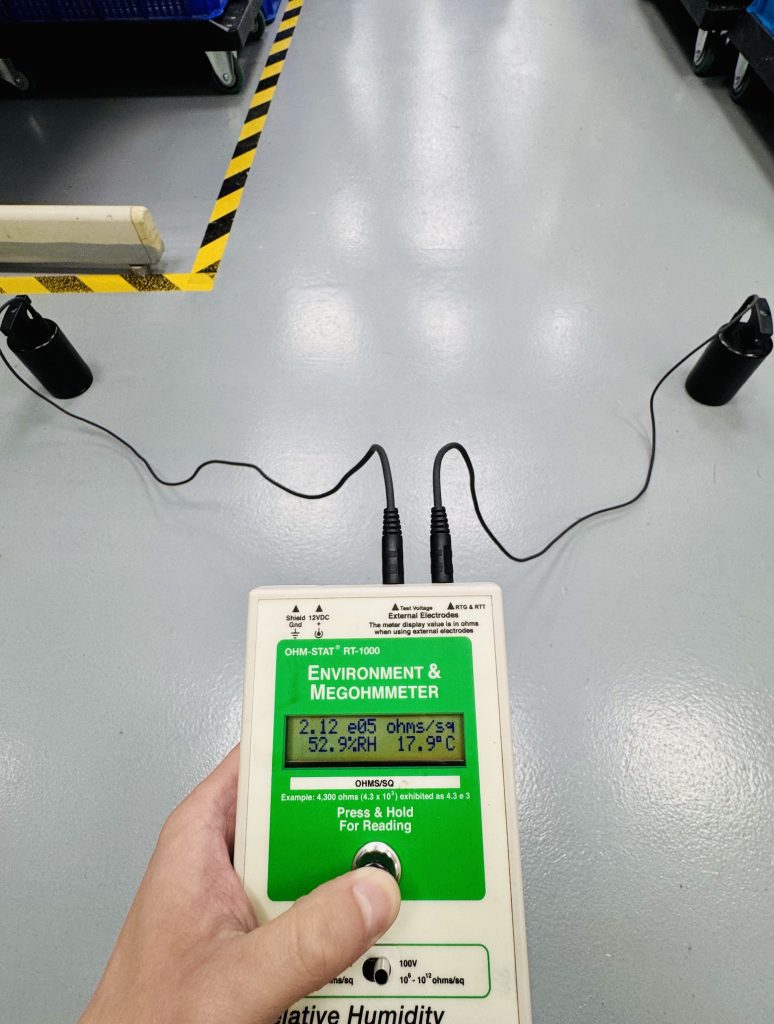

ESD Protect

Each department sets up test points and conducts regular impedance measurements. Ground-fault alarm systems are also installed to ensure grounding effectiveness and prevent ESD damage.

ESD Flooring

Ground-fault Alarm

ESD Control Map

Other Equipment

X-ray Inspection

X-ray Counter

ICT

BGA rework

PCB Router

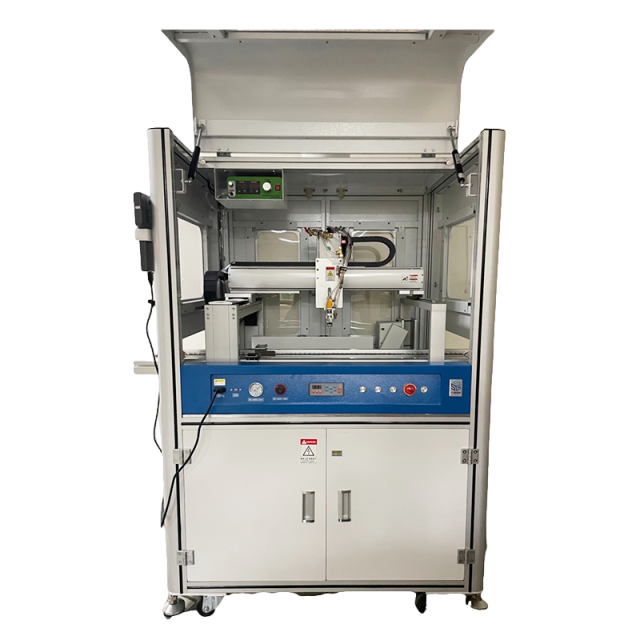

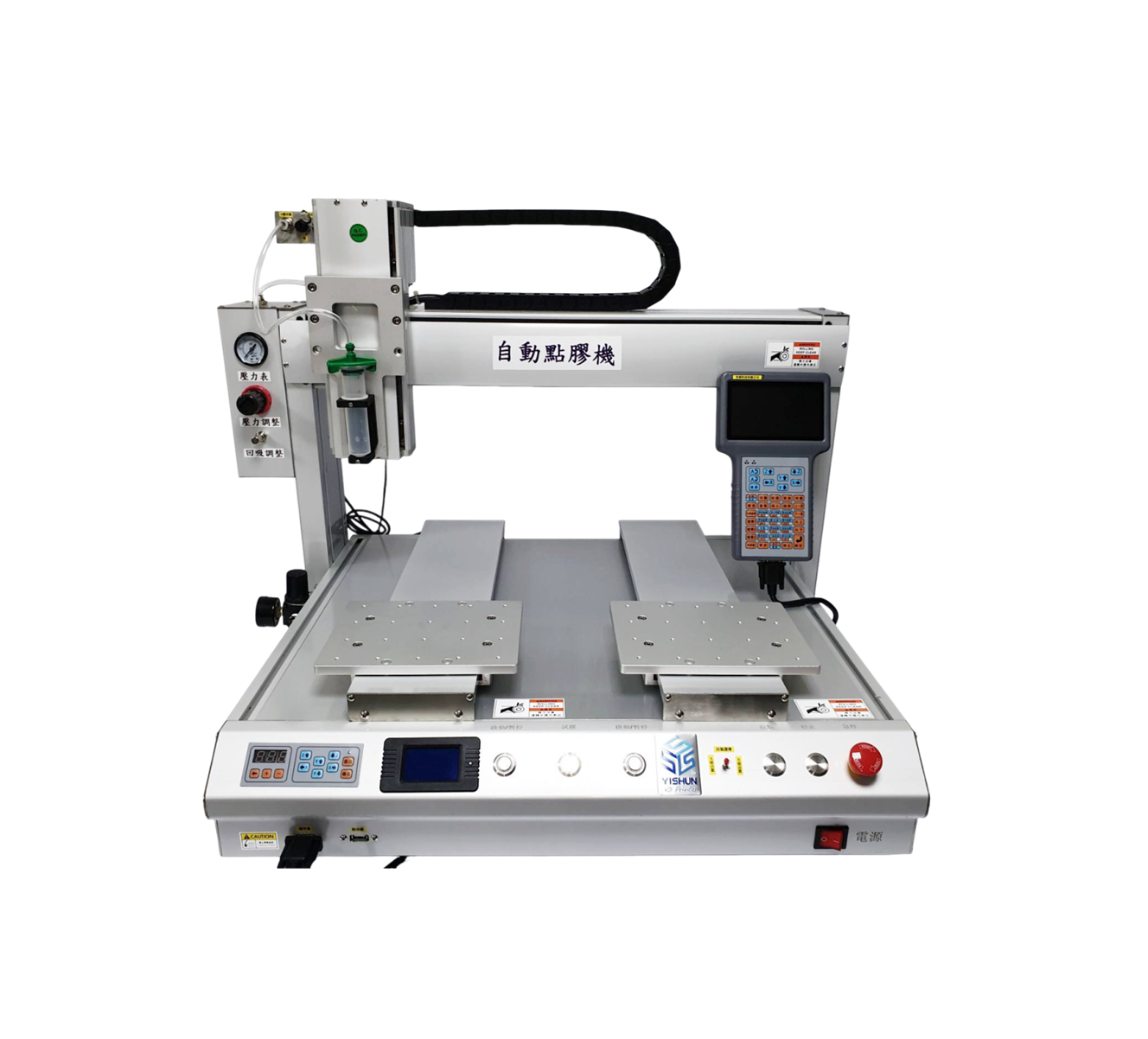

Auto Conformal Coating

Auto Spot Welding

Auto Coating